Fineplas China (FPC) was established in 1989 with over 15 years tooling and injection experience. We make use of the advanced technology and management system from Japan to apply on our production in China to achieve higher productivity and efficiency. We have operation in both China (Huizhou) and Japan (Namerikawa & Nanao city) and strive keeping to be the top tooling maker and injection services provider for the high-end market in Asia.

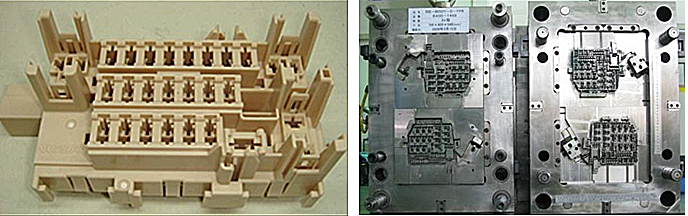

FPC offers the integrated engineering and manufacturing services of precision tooling design, mold manufacturing, product injection, assembly and inspection for the automotive industry, such as, connector, protector, relay box, fuse box, etc. This all requires precise tolerance and high quality control tooling, normally, it is controlled within 0.002mm tolerance in our tooling.

For the injection process, we work with Sodick on the V-Type injection machine (vertical) to further improve our injection quality by preventing the 'overpacking' as it is known that it will create the notch that induced stress concentration and causing the weakness point on the product. Meanwhile, by introducing the QCD management (Quality, Cost, Delivery), we provide the total solution to our customers.

In addition, we cooperate with the Hong Kong University of Science & Technology (HKUST) on the mold flow analysis program, Moldex 3D. It will strengthen our tooling design & injection knowledge to continuous improving our quality.

| 1) Closed Water Cooling System: | - Less water consumption and Higher cooling efficiency |

|

2) Insulation Jacket Injection | - Less energy consumed as the temperature can be kept in a certain level |

| 3) Water Curtain: | - Energy consumption reduced by 90% instead of using air-conditioning |

| 4) Electric Injection machine: |

- Energy consumption reduced by 30% comparing to the hydraulic type |

Sumitomo Wiring System (SWS), Omron

FPC Equipments & Facilities:

| Injection Machine | 40-110mt | 25 |

| Injection Machine | 150-450mt | 23 |

|

Vertical Injection Machine (Sodick, Nissei, Toshiba, Haitian) | 60-75mt | 2 |

| Inspection Machine | 6 | |

| Assembly Line | 7 |

| Grinding Machine | 8 |

| CNC Discharge | 8 |

| Wire Cut | 7 |

| Milling | 4 |

|

Machining Center (Sodick, Okamoto, Nagashima, Mitsubishi) | 6 |